EV charging cables are used to connect electric vehicle charging devices and charging infrastructure to transmit power to electric vehicles and are equipped with a certain amount of signal lines, control lines, power auxiliary lines, etc. to ensure accurate control of the entire charging process and safe operation. Charging cables are generally used in charging stations, parking lots, hotels, communities, garages, and other areas. Portable charging cables can be placed in the car.

introduction:

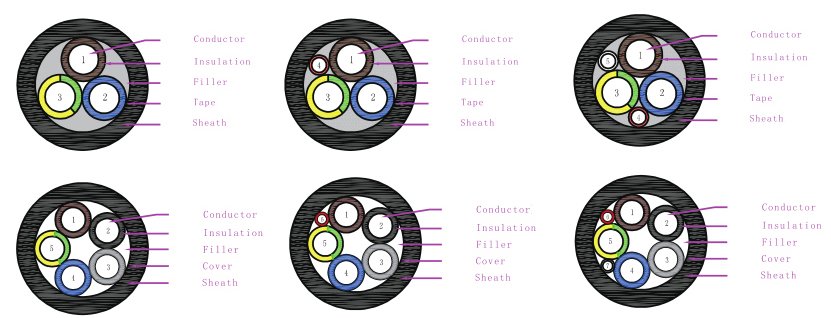

| Construction | Features |

| 1.Conductor | Rated temperature :-40℃~90℃ |

| Material: Bare Copper | Rated Voltage : AC 300/500V、 450/750V;DC 1000V |

| 2.Insulation | Flame Test :Testing method according to EN 60332-1-2 |

| Material: EVI-2 | Min Bending Radius: ≥6*OD |

| Color: Brown,Blue,Yellow/Green | Dielectric Voltage:2.5 kV AC for main core ,2.0 kV AC for CC/CP |

| 3.Filler | Low temperature impact :-40℃, No cracks |

| Material: PP Cord | Hot Shock:150℃/1h No cracks |

| 4.Tape | Oil Resistance :IRM902, 100℃*168h Tensile Strength Variation <±40% |

| Material:Non-woven fabrics | Elongation Variation<±30% |

| 5.Sheath | Crush resistance:Sq≤4, crush force≥4KN ; 4≤Sq≤35, crush force≥11KN; |

| Material: TPU | Resistance to Acid and alkali:168h, Tensile Strength Variation ≤30%; Elongation≥100%,Environmental Requirements:Compliant |

| Color: Any color | with RoHS2.0 and REACH |

Product description

| Construction | Features |

| 1.Conductor | Rated temperature :-40℃~90℃ |

| Material: Bare Copper | Rated Voltage: DC1500V |

| 2.Insulation | Flame Test:Testing method according to EN60332-1-2 |

| Material:EVI-2 | Bending Radius:≥6*OD |

| Color: Yellow/Green,Blue,Brown、Black、Gray | Dielectric Voltage:2.5kVAC for main core,2.0kV AC for CC/CP |

| 3.Filler | Low temperature impact:-40℃No cracks |

| Material:PP or cotton yarn | Hot Shock:150℃/1h No cracks |

| 4.Tape | Oil Resistance:IRM 902 100℃168h Tensile Strength Variation<±40%, |

| Material:Non-woven fabric | Elongation Variation<±30% |

| 5.Sheath | Crush resistance:Sq≤4crush force ≥4KN;4≤Sq≤35 crush force≥11KN |

| Material:TPU | Resistance to Acid and alkali:168hTensile Strength Variation≤30% Elongation ≥100% Environmental Requirements:Compliant |

| Color: Any color | with RoHS2.0 and REACH |

| Product number | Specification | Conductor twisted outer diameter |

Conductor resistance |

Reference allowable current |

Unshielded Complete outer diameter |

| 62893 IEC 126 | 2×10+10+P(2×0.75)+4×0.5 | 4.5 | 1.91 | 40A | 15.5 |

| 2×16+16+P(2×0.75)+4×0.5 | 5.7 | 1.21 | 63A | 18 | |

| 2×25+16+P(2×0.75)+4×0.5 | 7.1 | 0.78 | 100A | 24.5 | |

| 2×35+16+P(2×0.75)+4×0.5 | 8.4 | 0.554 | 125A | 25.8 | |

| 2×50+25+P(2×0.75)+4×0.5 | 10.2 | 0.386 | 150A/200A | 30.2 | |

| 2×70+35+P(2×0.75)+4×0.5 | 12.0 | 0.272 | 200A/250A | 34.7 | |

| 4×50+50+6×0.75 | 10.0 | 0.386 | 300A/350A | 38.5 | |

| 4×60+70+6×0.75 | 11.0 | 0.319 | 350A/400A | 43.5 |